Showroom Maintenance

Showroom Culture of Clean

We are here to introduce you to the AutoStone culture of clean developed to educate your dealership on best cleaning practices, methods and processes. You have just purchased the best automotive floor system for your automotive dealership. Your store has either/or all AutoStone produced and/or supplied tile in your showroom. Based on your showroom, you will have a different or modified approach to cleaning this area. AutoStone has (3) workshop floor systems that are we supply automotive dealership facilities. Regardless of which floor system you choose, all include our brightfinish, which is a permanent sealant, baked-in during the manufacturing process.

Brightfinish Ultra-Cleanable Technology

AutoStone’s brightfinish is a permanent sealant which seals the tile surface micropores. Tiles with a brightfinish are more resistant to staining and easier to clean than other tile products. These (3) AutoStone workshop and service drive floor tiles have an impervious surface which are enhanced with a brightfinish to deliver even better stain resistant performance properties.

Enhanced Impervious Surface Technology

An impervious tile is the highest performance standard in the porcelain tile industry. The definition of an impervious tile is a surface that absorbs moisture between 0.5% to 0.001%. At AutoStone, we think that 0.5% is too much absorbency, and in an automotive dealership will cause tiles to absorb oil, grease, petroleum, gasoline and other contaminants. When this happens, your tile surface will darken over use and this leads to potential hazards such as STF (slip, trip and fall) events. Petroleum and oils soaked surfaces can pose other hazards when not properly removed with regularly scheduled and proper cleaning practices. With the addition of our brightfinish we enhance our impervious tiles and reduce their absorbency to levels at the lowest end of the spectrum (0.001% or less). This means nothing is absorbed by an AutoStone workshop or service drive floor tile. AutoStone workshop floor systems are premium floor systems which are designed to resist staining and be easier to clean.

The Importance of Regularly Scheduled Cleaning Practices

Because nothing is absorbed by an AutoStone floor surface, contaminants will sit on-top of the floor surface until removed by your scheduled cleaning practices, or by a spot-clean. Properly conducted and scheduled cleaning is strongly recommended.

Cleaning Recommendations

We recommend daily scheduled floor cleaning with a floor scrubbing machine, use of a proper cleaner (de-greaser) and established protocols for spills, or “spot-cleans”. Clean floors provide a better customer and employee experience as well as reduce STF (slip, trip and fall) risk and also reduce potential fires which may result from spilled flammable liquids left un-addressed on the floor. Proper floor cleaning practices require the daily proper cleaning of your floors and established “spotclean” protocols to address spills of flammable liquids and other petrols to help reduce risk and improve workplace safety.

General Cleaning

General cleaning is an established daily cleaning procedure, done after your dealership closes and before it re-opens. We recommend dealers keep and maintain records to reflect “proper and regular cleaning practices and spill clean-up (spot-clean) protocols”. Proper cleaning includes the daily

use of a floor-scrubber-sweeper machine with a wet-vac and squeegee-blade to suck-up the dirty water and wipe your floor surface clean of chemical residues. In the process of cleaning your service facility, dealers may need to take additional cleaning steps to assure that floor surfaces

are properly cleaned. Hard-to-get areas sometimes don’t get cleaned with your floor scrubber-sweeper-wet-vac and squeegee blade machine. When your cleaning machines don’t get to all places, additional steps should be taken to assure that your dealership workshop and service drive floor always has that clean, fresh, bright and “like-new” look. Hard-to-get spots are places where your floor cleaning machine doesn’t cover on a regular basis.

Cleaning Hard-To-Get Places and Spot Spills

Your dealership culture, attention to detail and your cleaning regimen these cleaning tips can help your dealership look “like-new” for the life of

your dealership. For spot-spills and hard-to-get places, we recommend dealers invest in sponge mops (with lever activated wringers) and large

mop buckets (with wheels) for both your cleaning staff, and your tech’s (depending on your established practices) to help address these areas on

a daily basis. Having sufficient sponge mops, replacement sponge mop heads and buckets of clean water will deliver better results. We also

encourage dealers establish and publish a written protocol on who cleans what areas based on individual workspaces and shared workspaces to

assure that all areas are cleaned on a daily and regular basis. Addressing and assigning cleaning duties for hard-to-get areas and when spot spills

occur will help to build a strong team environment, pride in their workspace and overall better results for your dealership.

They can include areas such as:

- Against walls

- Around lift posts in tech bays

- Up against tech cabinets

- Up against equipment racks and machines

- Around drums, consumables, and storage areas

- Around center floor drains

- Around floor drains and vents

- At vehicle entry doors and exits

- The interior space of tech stations

Cleaning Equipment Examples For Hard-To-Get And Spot-Clean Efforts

We recommend the use of a sponge mop, as show below:

Sponge mop with long pole and wringer

lever activated sponge wringer

We do not recommend the use of a string-type mop

When selecting your mop buckets, we recommend that you select a singular bucket as shown below. If you are using a sponge mop with hand wringer, you will not require a dual tank mop bucket, which are designed for use with a string mop. You need to have the right equipment used in combination together

Reecommended mop bucket type

We do not recommend the use of a string-type mop bucket

Do's, Tips, & More

When implementing your cleaning strategy, make sure that your program includes the following:

- Mop equipment supplements your cleaning practices and does NOT replace recommended use of floor scrubber machine.

- Frequent replacement of consumables. Example: your sponge mop head should be replaced at least on monthly basis,

depending on the area of use. - Your dealership should have multiple sponge mops and buckets for use.

- Distinguish the difference between daily cleaning practices and “spot-cleaning”.

- Buckets of dirty water should be emptied after use and not left behind for the next person. When dirty water is left in buckets,

it gets used again-and-again. When dirty water is re-used, it contaminates your floor with oily, dirty and greasy water. - Oily, dirty and greasy water will elevate your STF (slip, trip and fall) risk and degrade your dealership appearance.

Spot-cleaning is addressing daily spills of chemicals (oil, grease, gas and all contaminants) that happen in the course of servicing vehicles. We recommend that there be an established practice on how such spills should be cleaned. Leaving spills on the floor increases your STF (slip, trip and fall) risk. AutoStone recommends that spot-cleaning be addressed quickly with the same cleaning process as outlined above.

Mopping Limitations and Expectations

Using only a mop is not a recommended cleaning process. Mops only sling around dirty water, which dries and leaves soap and dirt contaminants behind. Mops are best used for getting to hard-to-get places floor scrubbers can’t get to and for spot cleaning spills and similar temporary messes. Mops are to supplement your floor scrubbing machine practices, not replace use of a floor scrubbing machine.

Multi-Step "Sponge" Mopping

We have seen multi-step “sponge” mopping work for grout joints in showroom applications. This requires (2) sponge mops and (2) separate buckets of water. You can spray a light chemical in the joint and wipe it out with the 1st sponge mop and wring it out in the bucket. The 2nd sponge mop and clean bucket of water is to act as the final clean water rinse. In both cases, you need to empty the buckets of water, especially the 2nd bucket to make sure that you are not just re-applying chemicals to the grout joint. You can substitute the 2nd sponge mop with a good wet-vacuum system to suck up the chemicals. This low-tech manner can help get your grout joints back to a cleaner state.

De-greasing Cleaners + A clean water flood rinse

We encourage your cleaning crew to be very careful about the type of chemicals to use. We recommend that you use the appropriate cleaners for your showroom facility and your service drive and workshop areas. The chemical should be used according to the manufacturers recommend ratio. Regardless of the chemical you use to clean, we recommend your standard cleaning practice include a flood rinse with clean water after each chemical introduction.

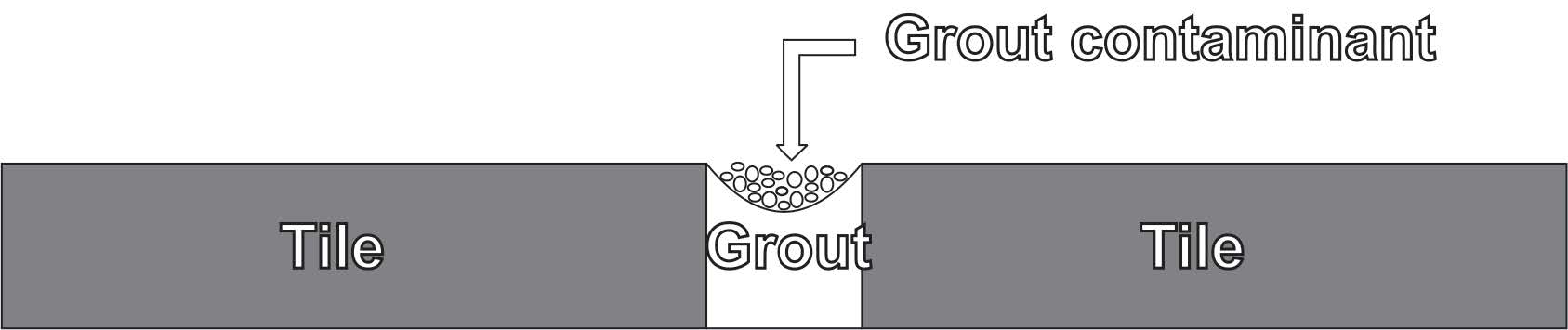

Grout Joints

One of the bigger cleaning issues is when dirty water and chemical residues are left behind on the tile surface and in the grout joints.

Whitening of grout joints is usually related to dried soap residue or efflorescence (caused by mineral deposits in water). Both

can be better controlled by sucking up all water from the joints and using clean water as a rinse to remove any remaining chemical.

Grout joints are the lowest point on the floor. Therefore all the contaminants usually end up in the grout joint. The best manner

and method to keep them clean and true in color is to have a machine that scrubs out the joints and sucks up the cleaning

chemical after scrubbing. Again, after this process, a good flood rinse will help remove any remaining contaminants and

remove the chemical residue that may remain on the tile and in the grout joint.

Tire Tracking - A Signature of Cleaning Residue

When you see rubber transfer on your floor that appears soon after cleaning, it is usually the indication that there is an acidic or similar chemical residue that remains on your floor. AutoStone recommended cleaners help reduce your concerns with tire tracking. If you use an non-AutoStone recommended cleaner, please follow the instructions on how to properly apply. If other cleaners leave a chemical residue behind which contributes to tire tracking, use a series of flood rinses to remove the residue. Acids will remain on the floor and need to be rinsed off a number of times with a clean water rinse.

Life-time Technical Cleaning Assistance

AutoStone is here to support your dealership for the life of your facility. As a reminder, if your cleaning practices diminish, for whatever reason, AutoStone is here to provide you life time technical cleaning assistance. To achieve the best cleaning results, use AutoStone recommended cleaners for you the specific location(s) in your dealership. We recommend the use of AutoStone dealerclean for your service drive and workshop floors. The added STF risk prevention aspect of this cleaner make it another great management tool improve workplace safety and reduce employee and customer injury on floors with chemical contaminants.

How To Achieve Better Cleaning Results

Former cleaning practices need to be re-evaluated and a new understanding of your floor system should be embraced. There are two components that need to be cleaned: 1) your tile surface and 2) your grout joint. Both can be addressed in the same cleaning process with correct and proper cleaning equipment and techniques.

Mopping Pros and Cons

- Mops supplement good cleaning practices. Mops should only be used to clean-up immediate spills and hard to reach areas. They should not supplant the use of a floor scrubbing machine.

- Mops only spread dirty water and contaminants around.

- Once the water evaporates from your floor, the dirt, soap and other chemicals/contaminants are left behind and on the

surface of your tile and in your grout joint. - Even the best mopping practices are insufficient to provide long-term, in-depth cleaning for your showroom environments.

Mopping Hazards To Avoid

- Mopping your floor will leave soap residue behind. When the cleaner dries, it leaves a film on your tile surface, which will not provide you the cleaning appearance you desire. Certain chemicals and contaminants can make your floor look dirtier.

- When soap residue is left behind, it can be easily re-activated with a light amount of water (misting from a light rain or even humidity). When soap is re-activated, it becomes very slippery and can negatively impact your DCOF (dynamic coefficient of friction) rating. Your DCOF level is your “slip-and-fall” rating. Soap residue will create a scenario for greater slip-and-fall accidents.

- Mopping leaves soap residue, dirt and other contaminants in your grout joint. Initially, you will see a white residue in your grout joints – after each mopping (once the water has evaporated). This “white” contaminant is the soap residue sitting on top of your grout, in the “U” channel that makes up your grout joint.

- Once the water has evaporated it leaves behind a chemical residue. This contaminant sits on top of the grout joint (not staining it), but remaining behind due to incorrect cleaning practices. Mopping is not the only culprit when grout looks this way. Dealers need to use a good floor scrubber-sweeper with a rotary brush and vigorous wet vacuum to suck up the dirty water, created during the scrubbing and cleaning process.

- A good regimen that includes using a floor scrubbing machine with a wet vacuum which sucks up the dirty water generated from the cleaning process. A good wet-vac process is the best way to remove all surface contaminants. Mopping does not provide this important step in keeping your tile surface clean and your grout joint free of such contaminants.

Proper Equipment For your automotive dealership

As previously mentioned, you should have a good operating floor scrubber-sweeping machine. While you can use a floor scrubber – we recommend the scrubber-sweeping option. The difference is significant and greatly impacts both the tile and your grout joint.

Your floor machine should have aggressive pads that will engage the floor with friction to scrub your floors clean. Your wet-vac should easily suck-up the dirty water and the squeegee-blade should help remove the remaining water from the floor surface.

Achieve Better Cleaning Results

If you follow these guidelines and keep vigilant on cleaning your service department and showroom, you can keep your dealership in a “like new” condition. The workshop and service reception floor tiles supplied by AutoStone come with our brightfinish, which aids your dealership with best cleaning practices. Clean floors result because your dealership cares about your facility and the appearance of your dealership. Clean floors means you have created a safer environment as you have reduced STF (slip, trip and fall) hazards and you reduce other workplace injuries and risk by being vigilant about removing flammable liquids that may have been spilled on you floors.

Buying and AutoStone Floor System is one of many important steps in building a better retail environment, service reception area and service workshop. That is why we focus on how our products are to be used and supported in your dealership environment.

AutoStone floors can be restored to “like-new again”. Keeping them in this type of condition is a daily practice that implements the correct procedures and awareness on your cleanliness expectations. When your dealership embraces a passion for clean, you will have a culture of clean. AutoStone is supporting your passion!