An American ClinkerShop tile built with higher STF performance.

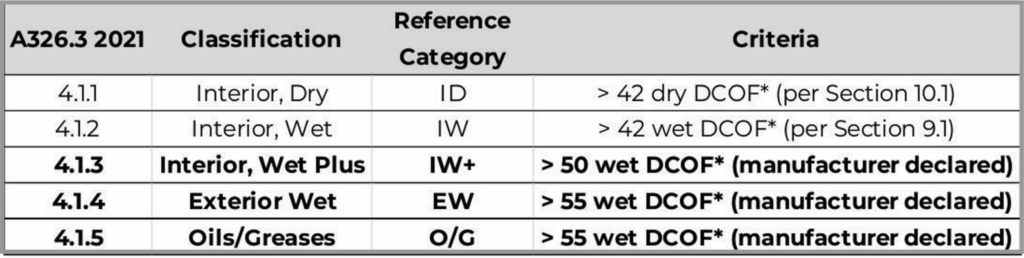

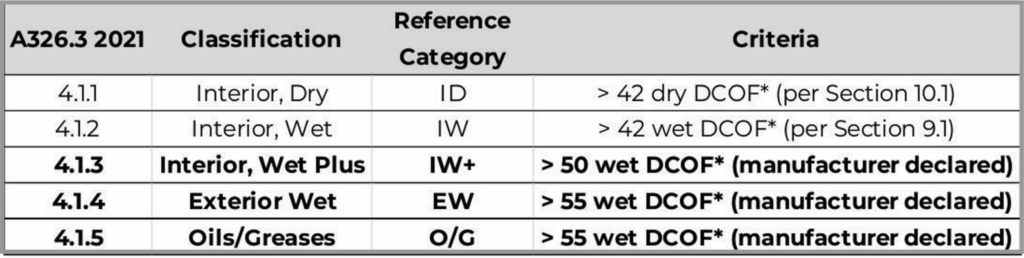

Complies with new ANSI A326.3 STF standards

4.1.3 IW+ Interior Wet Plus

4.1.4 EWX Exterior Wet

4.1.5 O/G Oils/Grease.

Click below to download

ClinkerShopUSA Tile Guidebook

Manage STF Environmental Risk

Your service drive is the most under-evaluated space in your dealership. Customers and employees meet on this small footprint while being exposed to greater STF risk.

How are you going to manage the risk you face?

AutoStoneUSA has better solutions to reduce the risk you face.

Your customers and employees will say, “that’s thoughtful”!

High Traction Surface

Complies to Higher ANSI DCOF Standards

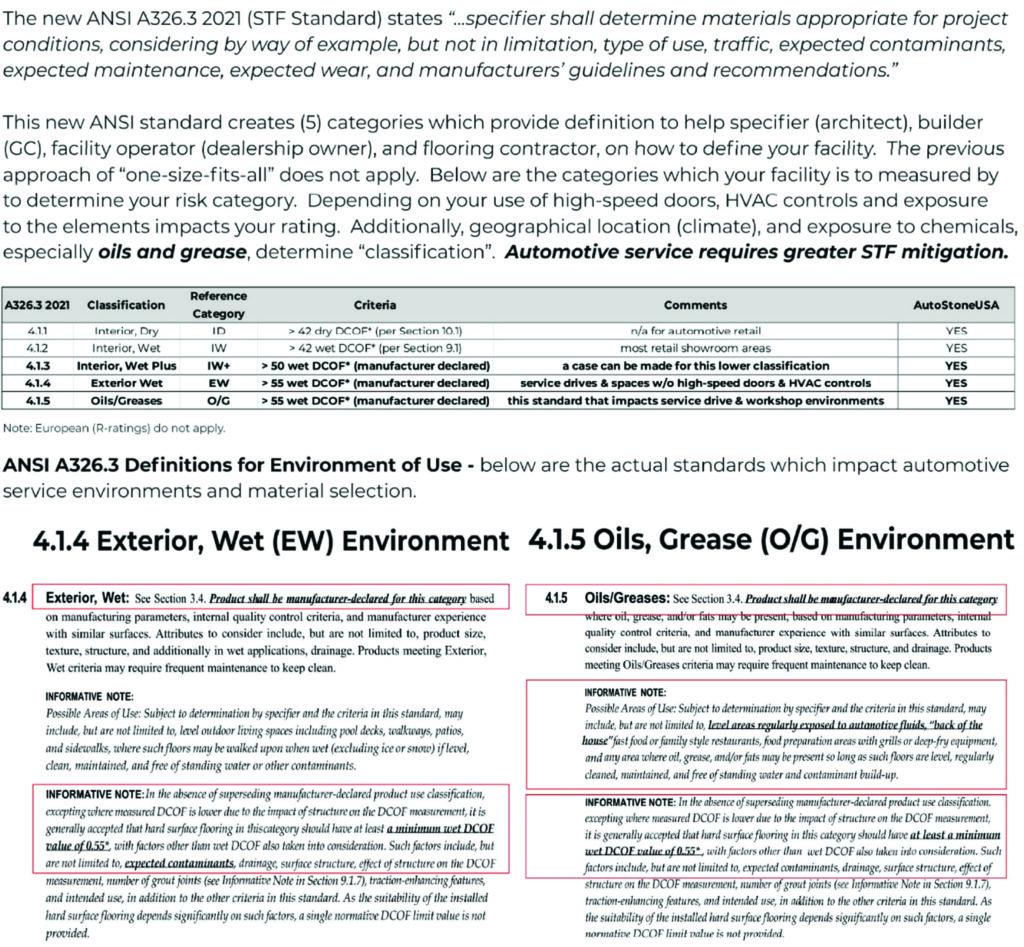

ANSI 326.3 (STF) Environments of Use

4.1.3 IW+ (Interior Wet Plus)

4.1.4 EX (Exterior Wet)

4.1.5 O/G (Oils & Grease)

ClinkerShopUSA includes AutoStoneUSA advanced surface technology. Super.Grip provides dealerships a flat surface design with a high texture (Super.Grip) to help you manage STF risk! No other clinker product compares!

Brightfinish

Ultra-Cleanable Technology

AutoStone’s ClinkerShopUSA is built from on our Clean.Tech – “ultra cleanable technology” designed to aid dealers with the cleaning practices. BrightFinish is a PERMANENT sealant that is baked-in, during the manufacturing process.

BrightFinish is PERMANENT, DURABLE and PERFORMS better because it provides a protective coating that resists permanent staining. AutoStoneUSA Clean.Tech advanced surface design does not trap or hold-on to rubber transfer, grease, oil or other contaminants, like traditional “sandpaper” textured surfaces.

AutoStone Aids Dealership

Cleaning Practices

AutoStoneUSA builds exclusively for the automotive dealership environment. We understand your environment of use and how your dealership operates.

We help dealers keep and maintain an environment that is maintained in a “like-new” condition for the life of the dealership.

When you follow our recommended cleaning and maintenance directions you will get a better outcome. Dirt, grease, and grime will remain on the surface until you remove it with proper proper cleaning efforts, which include the use of a floor scrubber sweeper machine and wet-vac to suck-up the dirty, contaminated water.

When you purchase AutoStoneUSA tiles, you receive “lifetime” technical cleaning assistance. We want to be your partner for life and help deliver better results and outcomes!

Chain-Rake QC Floor Testing

Eliminate Latent Installation Defects During Installation

Ask about the AutoStoneUSA “Chain-Rake” QC (quality control) process to assure that your workshop project delivers a lifetime of performance, function, and beauty. When it comes an automotive industrial floor, one of the risks ownership faces is latent warranty issues related to cracked-and-broken tile.

You can’t see if a tile is fully bonded to the substrate – but you CAN hear it when it isn’t!

When successfully implemented this QC process eliminates most future latent warranty issues that result in cracked/broken tile. Cracked/broken tile usually happens due to insufficient thin set applied to the back of the tile. This QC process helps identify those issues before the flooring contractor has left the project, so a fully bonded floor is realized, and future warranty issues are identified during the installation process.

Need Immediate Assistance?

point of contact

ready to order? Give us a call.

email us:

[email protected]

Phone:

214-393-4875

Copyright © 2019 AutoStone Floor Systems